Quartz glass, a remarkable material, boasts exceptional properties that make it indispensable across diverse industries. From its unparalleled optical clarity and resistance to extreme temperatures to its remarkable chemical inertness, quartz glass’s unique characteristics have driven innovation in fields ranging from high-precision optics to cutting-edge semiconductor technology. This exploration delves into the fascinating world of quartz glass, examining its properties, manufacturing processes, applications, and future potential.

Its versatility stems from its inherent composition and the various manufacturing techniques employed to shape it. Understanding these processes and the resulting material properties is key to appreciating its widespread use in demanding applications where performance and reliability are paramount.

Properties of Quartz Glass

Quartz glass, also known as fused silica, is a unique material with exceptional properties stemming from its pure silica (SiO2) composition and amorphous structure. Unlike crystalline quartz, its atoms are arranged randomly, leading to a distinct set of characteristics valuable in numerous high-tech applications. Its superior properties make it a material of choice in demanding environments where other glasses fall short.

Physical and Chemical Properties

Quartz glass boasts remarkable chemical inertness, resisting attack from most acids and alkalis, except for hydrofluoric acid and strong alkalis at high temperatures. This high resistance to chemical corrosion is a key advantage in applications requiring long-term stability in harsh environments. Physically, it’s a hard, brittle solid, transparent in its pure form, and exhibits a high degree of purity, minimizing impurities that could affect its optical and thermal characteristics.

Its density is relatively low compared to other glasses, contributing to its lightweight nature in certain applications.

Thermal Properties

A defining characteristic of quartz glass is its exceptional thermal stability. It possesses an extraordinarily high melting point, around 1700°C, significantly higher than most other glasses. This high melting point allows it to withstand extreme temperatures without significant degradation. Furthermore, it exhibits an exceptionally low coefficient of thermal expansion, meaning it undergoes minimal dimensional changes in response to temperature fluctuations.

This property is crucial in applications where thermal shock resistance is paramount, such as in high-temperature furnaces and optical components subjected to rapid temperature changes.

Optical Properties

Quartz glass displays remarkable optical transparency across a broad wavelength range, from the ultraviolet (UV) to the near-infrared (NIR) spectrum. This high transmission makes it ideal for optical fibers used in telecommunications, as well as in lenses and windows for UV and visible light applications. Its low optical dispersion means that light of different wavelengths travels through it with minimal separation, resulting in sharp images and high-quality optical performance.

Quartz glass, known for its high purity and thermal resistance, is a popular choice in various applications. Its properties differ significantly from other types of glass, like the security-focused Wired Glass , which incorporates a metal mesh for added strength. However, both materials highlight the versatility and diverse applications of glass in modern construction and manufacturing.

Additionally, it possesses high purity, minimizing light scattering and absorption, thus enhancing its overall optical clarity.

Mechanical Properties

Compared to other glasses, quartz glass exhibits higher compressive strength but lower tensile strength. This means it is resistant to compression forces but more susceptible to fracture under tension. Its hardness is also relatively high, contributing to its durability and resistance to scratching. However, its brittleness makes it prone to cracking under impact. This inherent brittleness needs to be considered during design and manufacturing processes to ensure the integrity of the final product.

Summary of Key Properties

| Property | Value/Description | Property | Value/Description |

|---|---|---|---|

| Melting Point | ~1700°C | Chemical Resistance | High (except HF and strong alkalis at high T) |

| Thermal Expansion | Very Low | Optical Transparency | High (UV to NIR) |

| Density | Relatively Low | Mechanical Strength | High compressive, low tensile |

Manufacturing Processes of Quartz Glass

Quartz glass, prized for its exceptional properties, is produced through various methods, each with its own advantages and disadvantages. The choice of method depends on factors like desired purity, scale of production, and final application. The most common techniques involve either vapor-phase deposition or melting pre-formed materials.

Flame Hydrolysis Deposition (FHD)

Flame hydrolysis deposition is a widely used method for producing high-purity quartz glass. In this process, silicon tetrachloride (SiCl₄) vapor is reacted with oxygen and hydrogen in a high-temperature flame. This reaction produces silicon dioxide (SiO₂) particles, which then deposit onto a rotating mandrel or directly onto a substrate. The resulting porous structure is then sintered at high temperatures to form a solid, transparent piece of quartz glass.

The process allows for excellent control over purity and allows the creation of complex shapes. However, it is a relatively slow and expensive method, limiting its application to high-value, specialized products.

Melting Techniques

Several melting techniques are employed to produce quartz glass, each offering a unique balance between cost, purity, and scalability. These methods include electric melting, gas melting, and plasma melting. Electric melting uses high-temperature resistance furnaces to melt high-purity quartz raw materials. Gas melting employs oxy-hydrogen or oxy-fuel flames to melt the raw material. Plasma melting uses a plasma arc to reach extremely high temperatures, enabling the melting of materials that are difficult to melt by other methods.

While these methods can be more cost-effective and scalable than FHD for some applications, they may yield a slightly lower purity compared to FHD.

Factors Influencing Quartz Glass Quality and Purity

The quality and purity of the resulting quartz glass are heavily influenced by several factors. The purity of the starting materials is paramount; even trace impurities can significantly affect the optical and thermal properties of the final product. Process parameters, such as temperature, pressure, and the rate of deposition or melting, play a crucial role in determining the homogeneity and structure of the glass.

Careful control over these parameters is essential for producing high-quality quartz glass. Furthermore, the design and maintenance of the manufacturing equipment are crucial in preventing contamination and ensuring consistent results.

Flowchart: Flame Hydrolysis Deposition (FHD)

The following flowchart illustrates the steps involved in the FHD process:[Start] –> [SiCl₄ Vaporization] –> [Mixing with O₂ and H₂] –> [Flame Hydrolysis Reaction (SiO₂ formation)] –> [Deposition onto Mandrel] –> [Sintering] –> [Inspection and Finishing] –> [Finished Quartz Glass]

Comparison of Energy Consumption and Cost-Effectiveness

The following bullet points compare the energy consumption and cost-effectiveness of different manufacturing methods:* Flame Hydrolysis Deposition (FHD): High energy consumption due to the high-temperature flame, resulting in higher production costs. However, it offers superior purity and control over properties.

Electric Melting

Moderate energy consumption and cost, suitable for large-scale production, but may result in slightly lower purity compared to FHD.

Quartz glass, known for its exceptional heat resistance, is a popular choice in high-temperature applications. Its durability makes it a key component in many industries, and its properties are often compared to other types of fire-resistant materials, such as those discussed in this article on Fire-Resistant Glass. Ultimately, the choice between quartz glass and other options depends on the specific needs of the project, but the superior heat tolerance of quartz glass remains a significant advantage.

Gas Melting

Moderate to high energy consumption depending on the fuel used, offering a balance between cost and purity.

Plasma Melting

Quartz glass, known for its exceptional thermal stability, is a fascinating material. Its high resistance to thermal shock makes it a suitable component in some high-end applications, contrasting with the more common approach of using multiple panes of glass like those found in Insulated Glass / Double Glazed Glass for improved insulation. Ultimately, both materials offer distinct advantages depending on the specific needs of the application, highlighting the diverse world of glass technology.

High energy consumption, but enables melting of materials otherwise difficult to process, making it suitable for specialized applications. The high energy cost leads to higher production costs.

Applications of Quartz Glass

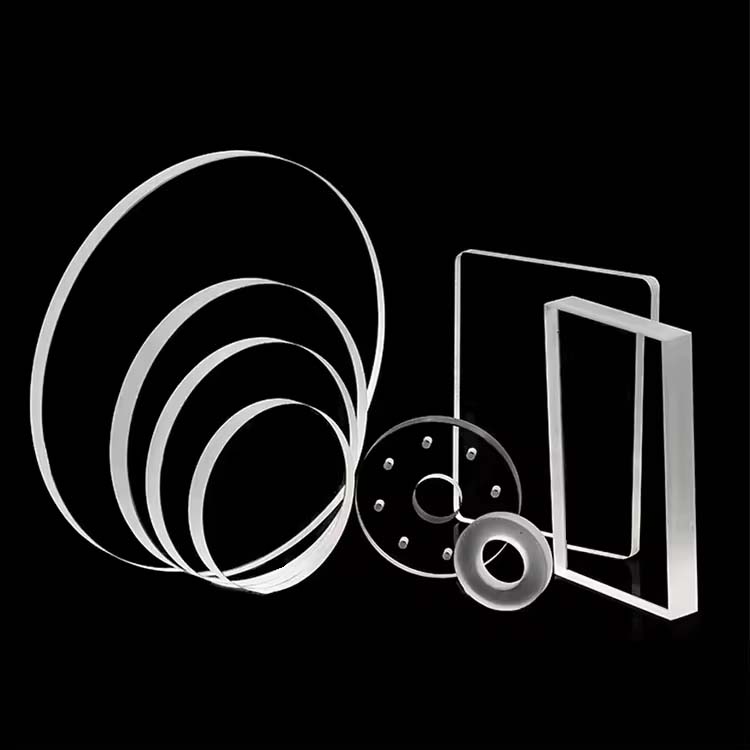

Source: wtglass.com

Quartz glass, with its exceptional properties like high transparency across a broad spectrum, excellent thermal shock resistance, and chemical inertness, finds applications in a wide range of industries. Its unique characteristics make it the material of choice for demanding applications where performance and durability are paramount. This section will explore some of its key uses.

Optical Applications

The exceptional optical properties of quartz glass, including its high transmission in the UV, visible, and near-infrared regions, low thermal expansion, and high refractive index homogeneity, make it ideal for various optical components. Its use in precision optics ensures accurate and reliable performance in demanding environments.

- High-precision optical lenses: Used in telescopes, microscopes, and laser systems, where precise focusing and minimal distortion are critical.

- Optical fibers: Used in telecommunications and high-speed data transmission due to their ability to transmit light signals over long distances with minimal loss.

- UV and IR optics: Employed in applications requiring transmission in the ultraviolet and infrared regions, such as spectroscopy and medical devices.

Semiconductor and Electronics Applications

The chemical inertness and high-temperature resistance of quartz glass are crucial in semiconductor manufacturing and electronics. Its use in this field minimizes contamination and ensures the integrity of delicate components during processing.

- Crucibles and boats: Used in crystal growth processes for semiconductors and other materials, preventing contamination and maintaining high purity.

- Diffusion tubes and masks: Employed in semiconductor fabrication processes, ensuring precise control over the diffusion of dopants into silicon wafers.

- Optical windows and lenses for lasers: Used in various laser systems, allowing for efficient transmission of laser light without degradation.

High-Temperature Applications

Quartz glass’s ability to withstand extreme temperatures without significant degradation makes it suitable for applications in high-temperature environments. Its low thermal expansion coefficient prevents cracking or shattering under thermal stress.

- High-temperature furnaces and ovens: Used in various industrial processes, such as glass melting, ceramic firing, and metal processing, where high temperatures are required.

- Lighting applications: Used in high-intensity discharge lamps and other lighting systems, where its ability to withstand high temperatures and UV radiation is crucial.

- Aerospace components: Used in certain aerospace applications where high-temperature resistance and chemical inertness are required.

Chemical Applications

The exceptional chemical inertness of quartz glass makes it highly resistant to corrosion by most acids, alkalis, and solvents. This property is essential in applications involving corrosive chemicals.

- Chemical reaction vessels: Used in various chemical processes, particularly those involving corrosive substances, preventing contamination and ensuring reaction control.

- Storage containers for corrosive chemicals: Provides safe and reliable storage of highly reactive or corrosive chemicals.

- Piping and tubing for corrosive fluids: Used in chemical plants and laboratories to handle corrosive liquids and gases.

Illustration: High-Precision Optical Lens

Imagine a perfectly formed, transparent lens, meticulously crafted from fused quartz. This lens, perhaps only a few centimeters in diameter, is flawlessly smooth and possesses exceptional optical clarity. Its purpose is to focus a highly intense laser beam with pinpoint accuracy for a medical procedure like LASIK eye surgery. The quartz glass’s inherent low thermal expansion ensures the lens maintains its precise shape even under the intense heat generated by the laser, preventing distortion and guaranteeing the success of the procedure.

The lens’s resistance to UV radiation further ensures its long-term stability and performance. The lack of internal stress within the fused quartz also contributes to its superior optical quality. This precise control over light is only possible due to the unique properties of quartz glass.

Advantages and Disadvantages of Using Quartz Glass

Quartz glass, also known as fused silica, offers a unique combination of properties that make it highly desirable for various applications. However, its use is not without limitations. Understanding both the advantages and disadvantages is crucial for making informed decisions about its suitability in specific contexts.

Benefits of Quartz Glass Compared to Other Materials

Quartz glass boasts exceptional thermal shock resistance, meaning it can withstand rapid temperature changes without fracturing. This is far superior to many other glasses and even some ceramics. Its high purity translates to excellent optical transmission across a wide range of wavelengths, making it ideal for applications requiring precise light control. Additionally, its chemical inertness ensures minimal interaction with most substances, preventing contamination and ensuring product purity.

Finally, quartz glass exhibits exceptional resistance to high temperatures and extreme environments, making it suitable for demanding applications where other materials would fail.

Limitations and Challenges of Using Quartz Glass

Despite its advantages, quartz glass presents certain challenges. Its high cost of manufacturing, due to the complex and energy-intensive processes involved, is a significant factor. Furthermore, quartz glass is relatively brittle compared to some other materials, making it susceptible to damage from impact or stress. The difficulty in machining and shaping quartz glass, requiring specialized techniques and equipment, adds to its overall cost and complexity.

Finally, its low refractive index compared to other glasses might limit its application in some optical systems requiring higher refractive power.

Cost-Effectiveness of Quartz Glass

The cost-effectiveness of quartz glass is highly application-dependent. In applications requiring its unique properties, such as high-purity chemical processing or high-temperature optical components, the superior performance often justifies the higher initial cost. However, for applications where less demanding materials could suffice, quartz glass might be economically unviable. For instance, using quartz glass for a simple window pane would be exorbitantly expensive compared to using soda-lime glass.

In contrast, its use in semiconductor manufacturing, where its purity and thermal stability are paramount, is considered cost-effective despite its high price.

Quartz glass, known for its purity and high melting point, offers unique properties for various applications. While typically clear, its versatility extends to colored variations, sometimes achieved through similar processes used for creating Tinted Glass , although the additives and techniques differ significantly. Ultimately, both types offer specialized optical and thermal characteristics valuable in diverse industries.

Environmental Impact of Quartz Glass Manufacturing and Disposal

The manufacturing process of quartz glass is energy-intensive, requiring high temperatures for melting and shaping. This contributes to greenhouse gas emissions. The raw material, typically high-purity silica sand, is abundant, but its extraction and processing can have environmental consequences, such as land disturbance and water usage. Disposal of quartz glass can also be a concern; while it is chemically inert and generally non-toxic, improper disposal could contribute to landfill waste.

However, the potential for recycling quartz glass is an area of ongoing research and development, aiming to minimize its environmental impact.

Comparative Table: Quartz Glass vs. Alternative Materials

| Property | Quartz Glass | Soda-Lime Glass | Borosilicate Glass |

|---|---|---|---|

| Thermal Shock Resistance | Excellent | Poor | Good |

| Optical Transmission | Excellent | Good | Good |

| Chemical Resistance | Excellent | Good | Excellent |

| Cost | High | Low | Medium |

Future Trends and Developments in Quartz Glass Technology

The field of quartz glass technology is experiencing a period of rapid evolution, driven by advancements in manufacturing techniques and the increasing demand for high-performance materials across diverse sectors. This progress is leading to the development of novel quartz glass types with enhanced properties and the expansion of its applications into cutting-edge technologies.

Emerging Manufacturing Trends

Several key trends are shaping the future of quartz glass manufacturing. The development of advanced melting techniques, such as plasma melting and vapor deposition, is enabling the production of higher-purity quartz glass with improved homogeneity and reduced defect density. Furthermore, efforts to optimize energy efficiency and reduce environmental impact are leading to the adoption of more sustainable manufacturing processes.

For example, the use of renewable energy sources in the melting process and the development of closed-loop recycling systems for quartz glass waste are gaining traction. These advancements are not only improving the quality of the final product but also contributing to a more environmentally responsible industry.

Advancements in Quartz Glass Properties

Research is actively focused on enhancing the properties of quartz glass to meet the demands of increasingly sophisticated applications. This includes efforts to improve its thermal shock resistance, UV transmission, and chemical durability. One promising area is the development of doped quartz glass, where the addition of small amounts of other elements can significantly alter its properties. For instance, doping with titanium can enhance its refractive index, making it suitable for advanced optical applications.

Similarly, research into creating composite materials that incorporate quartz glass with other high-performance materials is showing significant potential for creating materials with unique combinations of properties.

Future Applications of Quartz Glass

The unique properties of quartz glass make it a critical component in a wide range of emerging technologies. Its exceptional optical transparency makes it ideal for use in high-power lasers, advanced lithography systems for semiconductor manufacturing, and high-resolution optical imaging systems. In the field of renewable energy, quartz glass is increasingly used in solar energy applications, including concentrating solar power systems and high-efficiency solar cells.

Moreover, its high thermal resistance and chemical inertness make it suitable for demanding applications in extreme environments, such as aerospace and fusion energy research. The development of new types of quartz glass with improved properties will further expand its applicability in these and other emerging fields.

Potential New Applications in Emerging Fields

Beyond its established applications, quartz glass is poised to play a significant role in several emerging technological fields. For example, its biocompatibility makes it a promising material for biomedical applications, including implantable devices and drug delivery systems. Its high-temperature stability and chemical resistance make it suitable for use in extreme-environment applications, such as geothermal energy production and high-temperature chemical processing.

Furthermore, the development of flexible and transparent quartz glass opens up possibilities for use in flexible displays and wearable electronics. These applications are still in early stages of development, but the unique properties of quartz glass position it as a key material for future innovations.

Timeline of Significant Milestones

The development of quartz glass technology has been a gradual process spanning several decades. A simplified timeline highlights key moments:

| Year | Milestone |

|---|---|

| Early 20th Century | Early development of methods for producing fused silica. |

| Mid-20th Century | Development of high-purity quartz glass with improved optical properties. |

| Late 20th Century | Widespread adoption of quartz glass in semiconductor manufacturing and optical fiber production. |

| Early 21st Century | Advancements in plasma melting and vapor deposition techniques. |

| Present | Focus on developing doped quartz glass and composite materials with enhanced properties. |

Epilogue

In conclusion, quartz glass stands as a testament to the power of material science, exhibiting a unique combination of properties that continue to shape technological advancements. From its foundational role in optical instruments to its increasingly crucial function in high-tech applications, quartz glass’s remarkable characteristics ensure its continued relevance and promise exciting possibilities for future innovations. The ongoing research and development in manufacturing and application techniques only serve to enhance its already impressive capabilities, solidifying its position as a cornerstone material for years to come.

Essential Questionnaire

Is quartz glass the same as silica glass?

Essentially, yes. The terms are often used interchangeably. Quartz glass is a type of silica glass with a high degree of purity.

How is quartz glass recycled?

Recycling quartz glass is challenging due to its high melting point and the difficulty in separating it from other materials. However, some specialized facilities are beginning to explore recycling options.

What are the safety precautions when working with quartz glass?

Always wear appropriate safety glasses and gloves, as broken quartz glass can be sharp. Dust from grinding or cutting can also be a respiratory hazard.

How does the purity of quartz glass affect its properties?

Higher purity quartz glass generally exhibits superior optical transmission, improved thermal shock resistance, and reduced absorption of ultraviolet radiation.

What are some emerging applications of quartz glass?

Emerging applications include advanced optical fibers for high-speed communication, specialized components for extreme ultraviolet lithography, and novel biomedical devices.